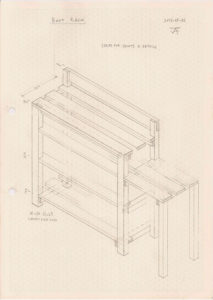

Ever since we moved here I’ve been wanting to build something out of wood. A boot rack for the porch is an ideal first project. I’d love to build a solid, heavy work bench first, which would make all future woodworking much easier than using the garden wall as a sawing horse, but I chose to make this first. It can serve as a practise piece: a boot rack will immediately be useful even if it’s a bit rough around the edges or indeed all over, whereas a wobbly work bench would be worthless.

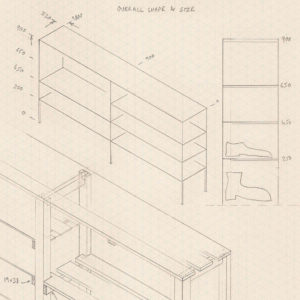

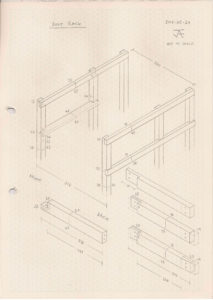

Isometric Delight

Searching for graph paper in my stationery drawer I came across an old pad of isometric drawing paper. What a delight! Sketching ideas and making neat scale drawings on that was as much fun as building the thing.

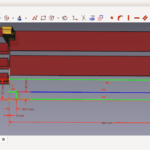

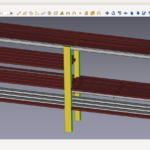

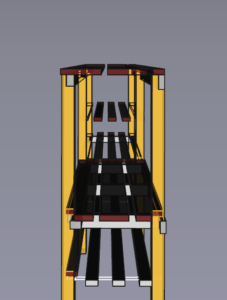

Of course I want to make drawings like these on the computer as well. One of the most exciting things computers could do, for me as a teenager, was CAD. I had lots of ideas about how my own CAD program would work. I recall programming a snap-to-nearest-point feature, in a mixture of BASIC and Z80 assembly language, which was very satisfying. Nowadays we have 3D CAD, even in the Open Source Software world where the best 3D modelling software by far is the truly excellent Blender. Its emphasis is on artistic rendering, whereas in second place is FreeCAD which is more suited to designing mechanical parts, and includes a constraint-based 2D drawing capability (“this line shall be the same length as that one”, etc.). FreeCAD is quite usable, but both its capabilities and its user interface need a lot of work to match the quality of Blender.

I started using FreeCAD because of the constraint drawing approach and because it looks like it would be fun and feasible to join in with developing it.

In case you are interested, you may download the FreeCAD project file here and open it in FreeCAD. (I was using FreeCAD v0.16.)

Recycled Wood

I made a list of parts using the wood sizes available from DIY supermarkets, but thinking of my friend Andy who set up the Southampton Wood Recycling Project, I drove over to East Midlands Wood Recycling CIC in Derby to see what they had. From their stock of long pieces I chose rough sawn pine to use for the back legs and bracing batons and a planed, rounded-edge larger piece for the front legs. The staff voluntarily cut the leg pieces into shorter lengths for me. From their main room full of piles of wood, I chose some cedar planks in various widths for the shelves. I liked the cedar because it was already varnished and because it smells lovely, but I have found it rather brittle and weak to be a good choice for shelves. I might add more strengthening batons underneath the front edges to prevent it from snapping when I perch my foot on it to tie my laces.

A Lesson

I learnt a lesson. Mixing many sizes of wood made for much more work than if I’d made all the legs the same size and all the batons the same size.

Mentions

Very cool. I was looking at designing a shelf in FreeCAD. This is a nice project to stumble upon for ideas. Best Regards!